4130 Carbon steel pipe

Classification :

Keywords:

Carbon steel pipe

PRODUCT DETAILS

4130 Carbon Steel Pipe is usually used in the quenched and tempered state. When the carbon content is at the lower limit, the steel can also be used as the carburized steel with higher central strength. In the medium-sized machinery manufacturing industry, it is mainly used to manufacture quenched and tempered parts with large cross section and working under high stress conditions, such as shafts, main shafts, and operating wheels, bolts, studs, gears, etc. under high load; In the chemical industry, it is used to manufacture welding parts, welding structures composed of plates and pipes, and high-pressure conduits with a temperature not exceeding 250 ℃ when working in medium containing nitrogen and hydrogen; In the steam turbine and boiler manufacturing industry, it is used to manufacture fasteners for work below 450 ℃, flanges and flange covers subject to high pressure below 500 ℃. The better weldability also makes 4130 Carbon Steel Pipe a popular choice in the aerospace industry, which is used to manufacture commercial and military aircraft components requiring high strength and low weight. Examples include gears, piston pins, etc. Other uses of 4130 steel include auto parts, cutting tools and drilling machines.

|

Item |

4130 Carbon Steel Pipe |

|

Length |

3-12M or as required |

| Outer diameter | 10mm-426mm |

| Wall thickness | 1-100mm |

|

Standard |

AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

|

Technique |

Hot rolled/cold rolled |

|

Surface Treatment |

Black/Peeling/Polishing/Machined |

|

Thickness tolerance |

Control with in the standard, OD:+/-1%, WT:+/-5% |

|

Material |

4130 |

|

Coatings |

Standard export packing |

|

Export packing |

Waterproof paper, and steel strip packed. |

Products Display

PACKING AND DELIVERY

Packing and delivery

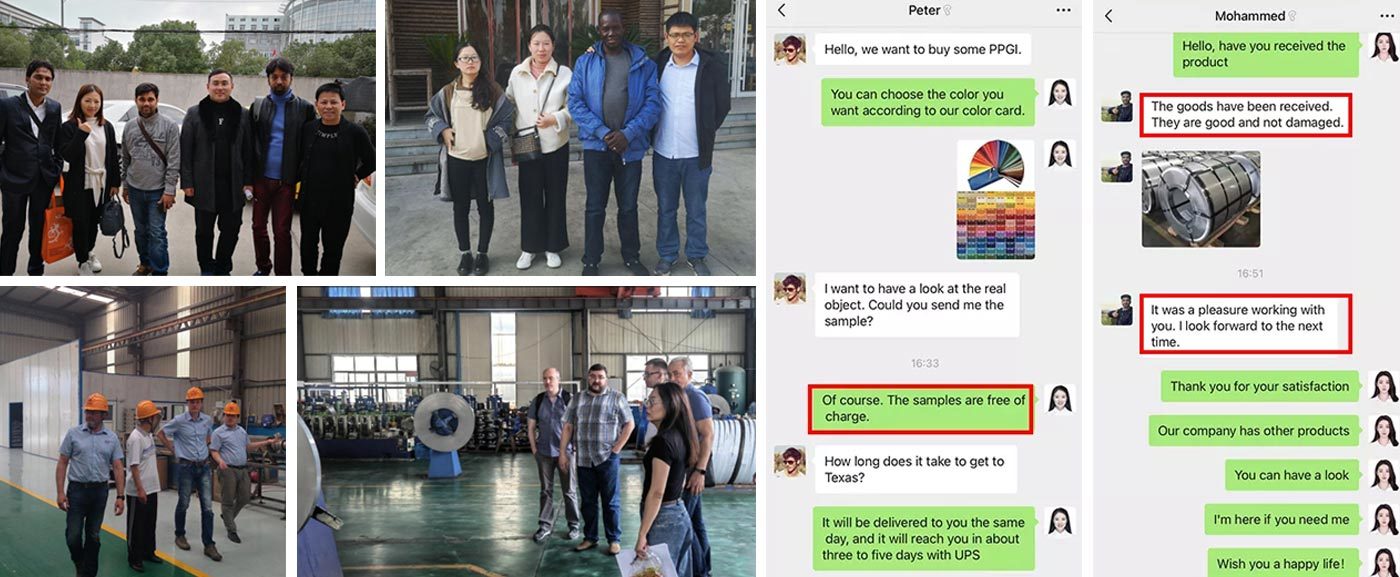

The company is a comprehensive steel production and supplier based in China and serving the world, providing domestic and foreign buyers with a full range of services including production, procurement, marketing, processing, logistics, and information.

FACTORY APPEARANCE

Strong manufacturing capabilities and complete industrial chain support. The factory covers an area of 20,000 square meters, with 8 advanced fully automatic cold bending production lines, 6 new hot rolling production lines, more than 20 feeders, 2 environmentally friendly hot-dip galvanizing production lines, and 2 oxygen-free annealing furnaces, maintaining an annual production capacity of 300,000 tons of steel.

APPLICATION AREAS

Widely used in automobile, petroleum, railway, bridge, construction, electric power, transportation, machinery, Marine light industry, home appliances, kitchen and other important fields. With excellent product quality, good reputation and innovative marketing concept,it ispopular at home and abroad.

CUSTOMER VISIT

RELATED PRODUCTS

GET A FREE QUOTE